CaPlast coating solutions

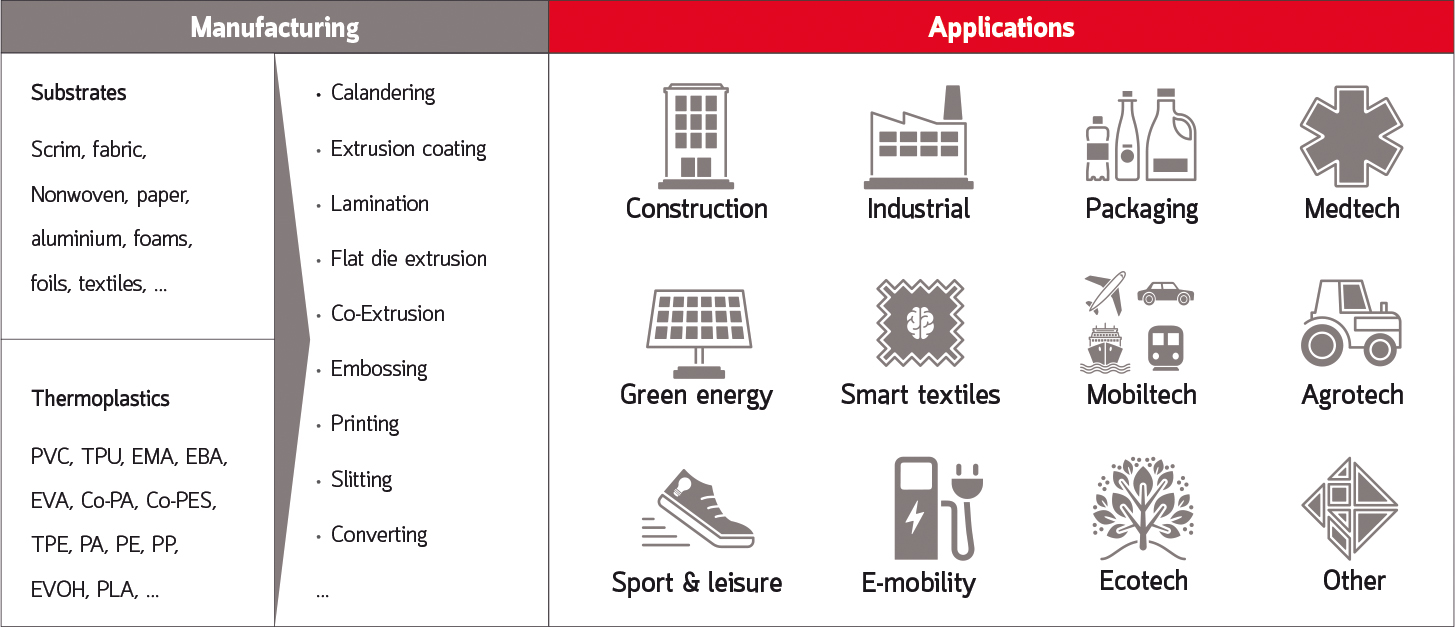

Functional coatings are omnipresent in our everyday life. Whether as a vapor barrier in buildings, as rain protection on clothing or as a barrier layer in automobiles. For several years, the trend has been towards multifunctional products with an increasingly complex layer structure. On the other hand, the aim is to make PVC and coated fabrics and foils increasingly recyclable, or even better, reusable. Every day we face the challenge of overcoming this apparent contradiction between comfort and sustainability. Thanks to one of the most modern production facilities in Europe, we are able to meet the most diverse customer-specific requirements quickly and economically. However, one thing always precedes production: expert application advice.

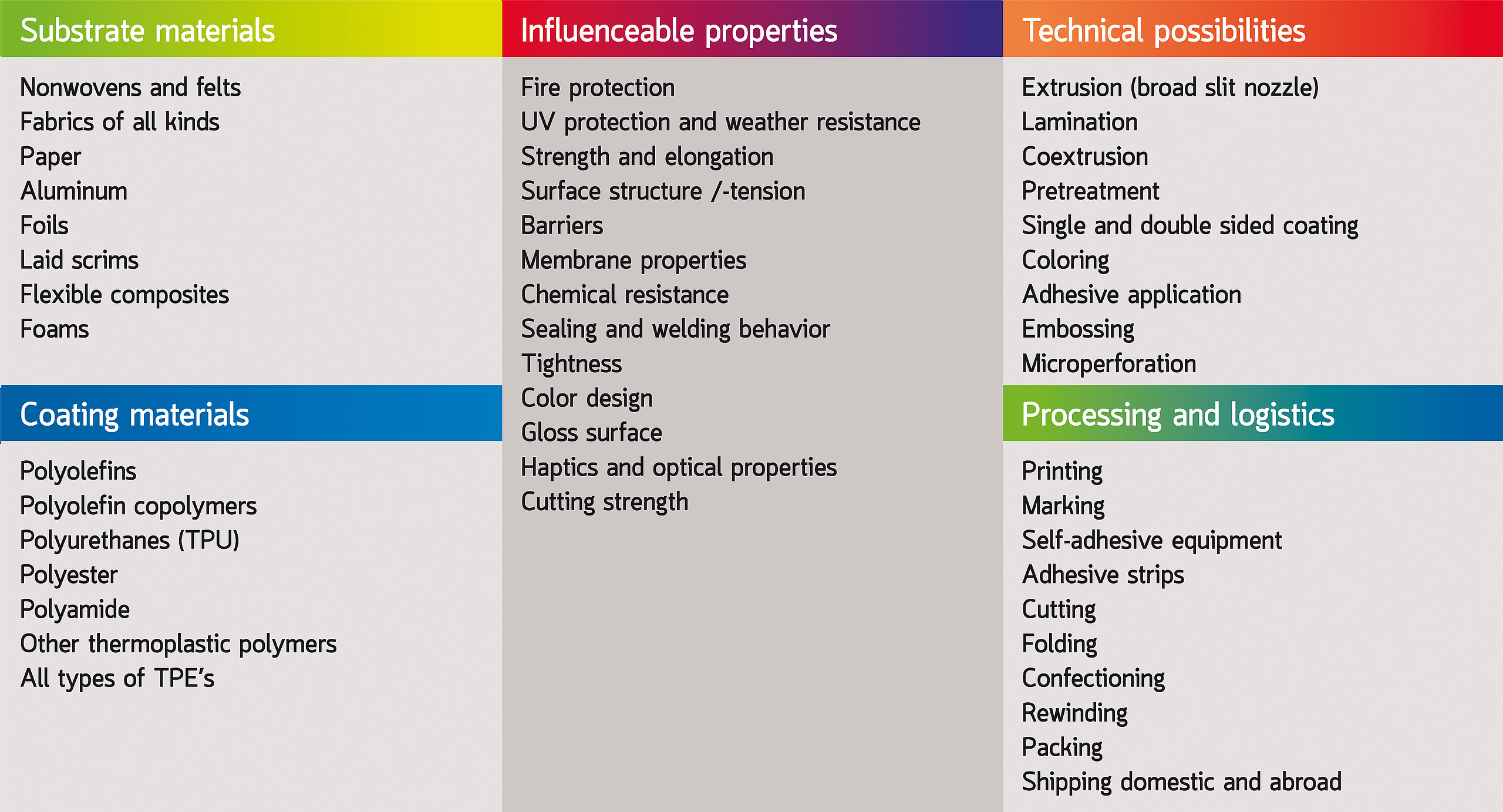

Our technical capabilities in the field of coating

CaPlast has four extrusion coating lines with die widths of 1,650 mm, 1,800 mm, 3,200 mm and 3,500 mm. On all lines, we can combine up to three substrates by means of one coating, i.e. produce 6-layer composite materials in one process step.

Almost any number of raw materials and additives such as inks and stabilizers can be combined. The maximum coating width is around 3,400 mm, depending on the coating raw material. On two coextrusion lines, the coating compound can additionally be separated into up to three layers in order to integrate certain barrier properties in a film or to separate an adhesion-promoting coating of a substrate from the final, top coating.

Numerous pre- and post-treatment methods give the products the necessary properties as well as the desired finish. This results in high-gloss, matte or embossed surfaces. Already in the coating process, the products can be printed or cut to the desired final size for a multi-use application.

Our technical capabilities in the field of packaging

CaPlast has extensive finishing lines of various widths for cutting commercial goods to size, full-surface 2C printing up to a width of 3 m or the application of hotmelt adhesives and adhesive tapes. This finishing is in particular demand for applications with seam sealing or overlapping webs.

Cuts from around 2 cm wide in multiple-ups are also possible without any problems. This value-added stage is rounded off by corresponding semi- or fully-automatic packaging stations.

Our sister company Now Contec specializes in converting and finishing technical nonwovens and films and complements the CaPlast range with state-of-the-art technical equipment for rewinding, printing, self-adhesive finishing, cutting, web folding and packaging.