CaLiner - the environmentally friendly, fabric-reinforced tarpaulin fabrics

We have redefined tarpaulin fabrics

Tarpaulins for agricultural buildings, large tents, marine tarpaulins, pool covers, bulk packaging and much more have long been the domain of PVC. We wanted to change that, because weight, stiffness, plasticizers as additives, the development of toxic fumes in case of fire and difficult recycling are just some of the disadvantages of this material. So we set out to redefine tarpaulin materials. Our answer: the TPO-based fabric tarpaulin CaLiner.

The advantages of TPO-based tarpaulin fabrics

The CaLiner fabric tarpaulin based on thermoplastic polyolefins meets three essential market requirements in one product: UV-resistant, difficult to deflammable, recyclable. In addition, it offers a whole range of advantages for every application:

- 50% lighter,

- 50 % longer service life than comparable competitor products

- Better light diffusion

- Good fire properties

- Flexible and easy to apply

- Can be welded and glued

- For temperatures down to -40 °C + 80 °C

- Pure, 100 % recyclable

- No expansion of the material at high temperatures

- Odorless, free of plasticizers and solvents

- Easy to clean with soap and water

- Suitable for contact with food

- Different tints possible

Polyolefins and the environment

PVC is on the retreat across the board because of the potential danger to health and the environment. Thermoplastic polyolefins do not contain substances that are hazardous to health, such as solvents and plasticizers. TPO-based products emit virtually no pollutants into the environment, and they do not emit toxic or corrosive fumes in the event of a fire. When TPO materials are burned, essentially only carbon dioxide and water vapor are produced.

Polyolefins are also easy to recycle. As with any recycling process, the purer the better. That's why, in the case of fabric-reinforced tarpaulin fabrics, we focus on developing single-variety products in which the fabric and coating are made exclusively of TPO.

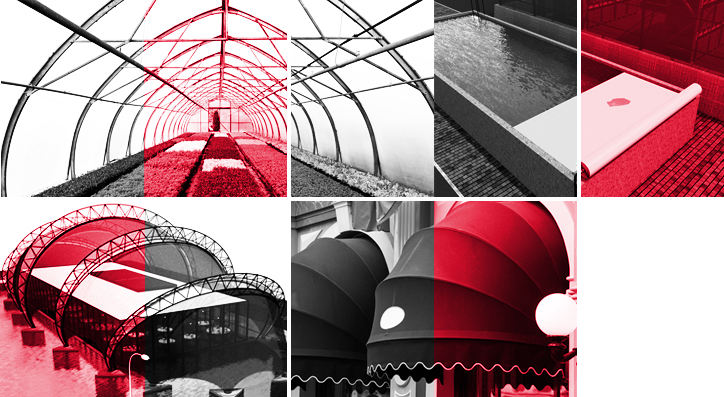

Possible applications of CaPlast TPO tarpaulin fabrics

- partition curtains/partition walls sports halls

- Keder tarpaulins

- Mobile construction (tent halls)

- Protective films in the leisure sector such as pool covers, boat tarpaulins, cover films for garden furniture, etc.

- Awnings and sun protection

- Foil greenhouses, greenhouse tunnels, agricultural foils

- truck tarpaulins

- scaffolding tarpaulins

- large format printing

Be on the safe side with TPO

Our solutions for TPO-coated tarpaulin materials give your products decisive competitive advantages in terms of environmental protection and health and safety. Our sales department will be happy to advise you on your desired application and the determination of the necessary material properties.