TPO-coated pipe liner – CIPP

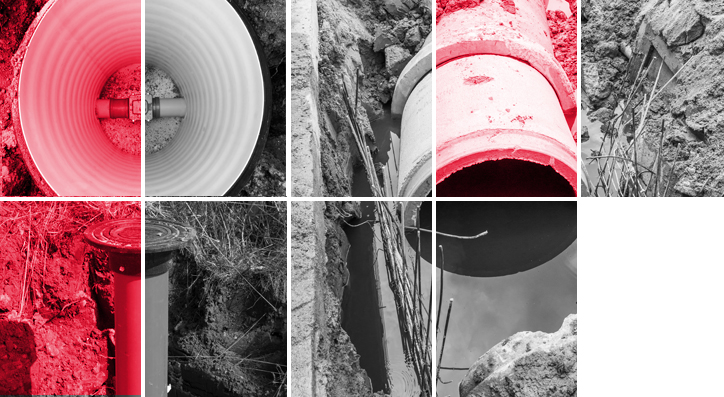

CaPlast has a sustainable and innovative growth product in its portfolio following the acquisition of coating expert AerO Coated Fabrics B.V., based in Tilburg, Netherlands: PVC-free pipe liners for trenchless sewer rehabilitation. Instead of costly replacement of leaking and corroded pipes, the pipes are repaired on site.

In the CIPP (Cured-in-Place-Pipe) process, a non-woven or polyester fabric hose impregnated with synthetic resin is drawn into the pipe or sewer and then cures. The smooth and absolutely leak-proof epoxy coating prevents pollutants from entering the drinking water and improves water pressure. At the factory, the hose liners are additionally coated for improved abrasion resistance, temperature and chemical resistance.

True to the sustainable corporate orientation of CaPlast and parent company KAP AG, we do not use PVC in the coating of the pipe liners and thus do not use materials that are potentially hazardous to health. Instead, the robust yet flexible composite material in AerO Coated Fabrics is coated on the outside with an environmentally friendly and extremely durable TPO layer. Of course, the product has all approvals and is certified suitable for drinking water. These specifications are possible:

- Thickness of the substrate: 0.5 to 10 mm

- Thickness of the coating: 0.2 to 2 mm

- Maximum width: 2.2 m

- Coating: TPO