Contract finishing of technical textiles

CaPlast offers industrial applications and contract coating plus all-round service

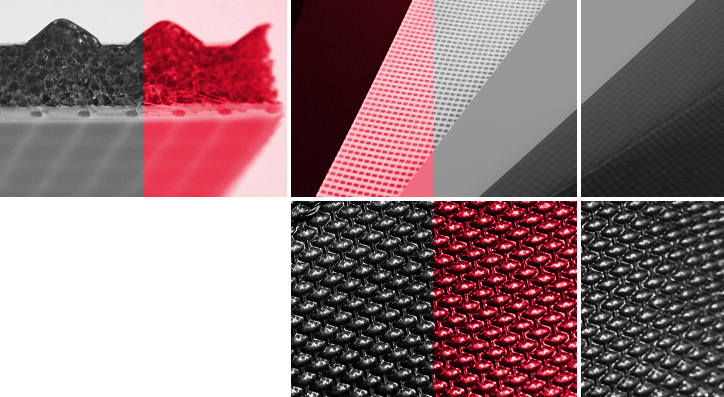

Modern technical textiles are multifunctional high-tech products. With an innovative coating, we not only give your products the desired functionalities, but also a high-quality appearance and interesting effects such as leather look and graining. The range of our contract coating services extends from simple, single-sided PE or PP coatings to complex co-extruded, 3-layer TPU, PA or COPO products for construction, industry, agricultural applications or use in the military sector. Simultaneous co-lamination of reinforcing fabric and/or substrate is also possible.

The individual product conception is in the foreground

We query the product requirements and develop a customized solution for the coating structure to achieve functionalities such as light and opaque, UV and infrared absorption, antibacterial effect or special colorations.

Thanks to the high manufacturing flexibility and our decades of experience in coating and finishing technical fabrics and nonwovens, we can produce even seemingly unsolvable tasks in a process-safe manner. Even difficult polyolefin layers, which place high demands on the chemical conditions during extrusion coating, can be transformed into a product with adhesion promoters. Substrate heating by pre-heating rolls, corona pre- and post-treatment or infrared heating of the substrate improve adhesion. The product properties can also be specifically influenced by co-laminating additional fabric layers and films.

A selection of possible functionalities

- Waterproof

- Diffusion-tight or diffusion-open

- Tear resistant

- Stretchable or tensile

- Light and opaque

- UV and IR absorbing

- UV-resistant

- Antifungal, antibacterial

- Temperature resistant

- Flame retardant

- Self-adhesive

- Thermo adhesive

- Stabilizing

- Slip resistant

- Printable

- Weldable

- and more

Your requirement is not listed? Then please contact us. Surely our plastics experts already have a solution. If not, it will also be found for challenging applications.

Process reliability and traceability

We continuously record the substrate and coating thicknesses during the entire production process by means of a non-contact differential measurement. If necessary, this enables the coating thickness to be adjusted immediately via the control of the automatic nozzle. The process control together with the storage of batch-related weight and recipe data allows complete traceability of the coating quality.